Lifting & Rigging Blog

Mastering Industrial Lifts: Your Guide to AmericanXpert Lifting and Rigging Equipment

When a single lifting mishap can halt your entire operation, choosing the right lifting sling is more than important—it’s critical. At AmericanXpert, our team brings over 50 years of combined experience in the rigging and lifting industry. We know what it takes to handle materials safely and efficiently, and we draw from industry standards, including OSHA guidelines, to provide trusted guidance.

In this comprehensive guide, we explore round slings, web slings, endless slings, and stage slings, along with the essential rigging hardware that supports them. You’ll find clear definitions, side-by-side comparisons, compliance requirements, maintenance best practices, and insights into the latest material handling innovations.

This guide helps you choose sling types, materials, and load capacities. It offers practical advice and real-world examples. Use it to help your team perform at their best while keeping safety a priority.

What Are the Core Types of Lifting and Rigging Gear in the AmericanXpert Lineup?

AmericanXpert offers a focused range of high-performance lifting slings designed for demanding industrial applications. We offer endless polyester round slings, polyester web slings, and Steel-tex stage slings. Each type is designed for different lifting tasks. Understanding these sling categories sets the stage for our upcoming comparison of their unique features and benefits.

What Exactly Are Endless Polyester Round Slings and Where Do They Shine in Industry?

Endless polyester round slings are strong, tube-like loops made from fabric. They help spread weight evenly on heavy items. This design greatly improves safety and holds odd shapes securely. Their loop design has no end fittings. This allows for a full 360° rotation around the load. It reduces wear and extends the operational life.

Key industrial applications include:

- Steel beam placement for structural assembly on construction sites.

- Machinery installation within manufacturing facilities, demanding gentle handling to prevent surface marring.

- Pre-cast concrete lifting where consistent load distribution is vital to avoid fractures.

By employing endless polyester round slings to cradle challenging loads, operators can minimize stress points and streamline lifting operations.

How Do Polyester Web/Flat Slings Stand Out, and What Are Their Key Advantages?

Polyester web/flat slings are constructed from woven polyester fabric, offering a balance of strength, flexibility, and abrasion resistance. They are a versatile choice for a wide range of lifting tasks, providing excellent load stability and surface protection.

| Chracteristic | Advantage |

| Woven Polyester Construction | Good abrasion resistance and flexibility |

| Flat, wide lifting surface | Distributes load evenly, minimizing pressure on the load |

| Available with various eye types | Offers versatile attachment options |

The flat, wide surface of polyester web slings promotes uniform wear distribution and gentle handling, making them ideal for many industrial applications.

What Are Steel-tex Stage Slings, and What Makes Them Unique?

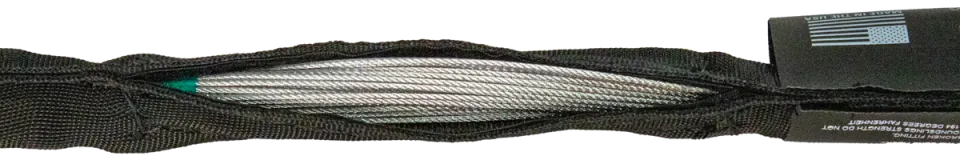

Steel-tex stage slings are engineered with Galvanized Aircraft Cable (GAC) for exceptional strength and durability, particularly suited for heavy-duty lifting and rigging in demanding environments. Their robust construction provides superior resistance to high temperature, making them a reliable choice for critical lifts.

| Chracteristic | Advantage |

| Galvanized Aircraft Cable (GAC) construction | High tensile strengthand excellent durability |

| Resistant to high temperature | Able to maintain load to up to 400 F degrees |

| Low stretch under load | Provides precise load control and stability |

The inherent strength and resilience of Steel-tex stage slings make them indispensable for Stage, theater, and entertainment rigging.

Which Rigging Hardware Components Seamlessly Integrate with AmericanXpert Lifting Gear?

Rigging hardware encompasses a range of essential components like shackles, hooks, and hoists that connect with slings to create a robust and secure lifting system. While AmericanXpert focuses on slings, understanding compatible hardware is crucial for complete lifting solutions.

- Shackles securely link slings to lifting points via high-strength pins for reliable load attachment.

- Hooks offer rapid connection and disconnection for dynamic lifting tasks.

- Hoists provide mechanical leverage and precise load positioning with controlled lifting speeds.

Integrating slings with the correct hardware ensures complete load control.

What Materials are used in AmericanXpert Lifting Slings?

Polyester and Galvanized Aircraft Cable (GAC) are the primary materials used in AmX lifting slings, each bringing unique strength and flexibility characteristics crucial for specific lifting scenarios.

| Material | Attribute | Lifting Application |

| Polyester | High resistance to abrasion, good elasticity | General lifting, shock absorption, outdoor use |

| Galvanized Aircraft Cable (GAC) | Exceptional tensile strength and durability. Heat resistant up to 400 degrees | Stage, theater, and concert rigging , no need for backup rigging. |

Choosing the right material foundation enhances safety and performance as we move on to compare sling types in the next section.

How Do AmericanXpert Endless Polyester Round Slings, Polyester Web Slings, and Steel-tex Stage Slings Compare in Industrial Lifting?

Comparing AmericanXpert's sling offerings reveals key differences in their construction, load capacity, and handling versatility, guiding you toward the optimal choice. Examining material variations and specific use-case scenarios clarifies the distinct criteria for each sling type before we delve into detailed comparisons.

What Distinguishes Polyester Round Slings from Polyester Web/Flat Slings?

Polyester round slings and polyester web slings are made differently. This affects how they handle loads. It also influences which lifting tasks they are best for.

| Sling Type | Construction | Characteristic |

| Endless Polyester Round Sling | Seamless tubular core | Cradles irregular shapes, 360° rotation reduces wear |

| Polyester Web/Flat Sling | Woven flat webbing | Distributes load evenly, good for flat surfaces |

Endless round slings excel at cradling irregular loads and offer superior wear resistance due to rotation, while polyester web slings provide excellent surface contact and stability for more uniform loads.

When Is a Steel-tex Stage Sling the Superior Choice Over Other Sling Types?

A Steel-tex stage sling is the best choice when you need strong, durable, and cut-resistant materials. This helps maximize service life and ensure safety. Common scenarios favoring Steel-tex slings include:

- Lifting sharp-edged materials like steel coils or fabricated metal parts where synthetic slings might be cut.

- High-temperature environments where synthetic materials may degrade.

- Applications requiring minimal stretch for precise load placement and stability.

The superior strength and cut resistance make Steel-tex slings the more advantageous choice for the most demanding lifting patterns.

How Do Load Capacities and Safety Factors Differ Across Sling Types?

Load capacity and safety factors vary based on the sling's design, material rating, and the specific hitch configuration used, all ensuring safe operation within defined limits.

| Sling Type | Typical Working Load Limit (WLL) Range | Standard Safety Factor |

| TwinTex Round Sling | 2,600 lbs to 90,000 lbs | 5:1 |

| PowerPlus Web/Flat Sling | 1,600 lbs to 30,600 lbs | 5:1 |

| Steel-tex Stage Sling (GAC) | 5,300 lbs to 8,400 lbs | 5:1 |

A thorough understanding of working load limits (WLL) and safety factors is essential for precise load planning before we address compliance requirements.

What Are the Crucial Safety Standards and Compliance Mandates for Lifting Slings?

OSHA and ASME standards provide essential guidelines for lifting and rigging equipment, ensuring operator safety and preventing equipment failure. Adhering to these regulations is the foundation of a strong safety program, setting the stage for detailed inspection protocols.

What Do OSHA and ASME Standards Dictate for Lifting and Rigging Equipment?

OSHA 1910.184 and ASME B30.9 establish minimum requirements for sling construction, safe usage practices, and inspection frequencies to prevent accidents.

OSHA 1910.184 outlines requirements for sling manufacturing, labeling, and operational limitations.

ASME B30.9 details specifications for synthetic slings, including mandatory identification tags and recommended periodic inspection schedules.

OSHA and ASME Standards for Lifting Operations

OSHA 1910.184 and ASME B30.9 offer critical guidance on the design, safe application, and inspection of lifting and rigging gear to avert accidents. These standards define the baseline requirements for sling construction, safe handling, and inspection intervals.

Occupational Safety and Health Administration (OSHA), 1910.184 (Slings)

This regulation comprehensively covers various facets of sling safety, including their build, markings, and usage restrictions.

ASME B30.9: The Standard for Sling Safety

ASME B30.9 specifies the mandatory requirements for synthetic slings, covering aspects like identification tags and inspection frequencies. The ASME B30.9 standard addresses the fabrication, attachment, usage, inspection, testing, and upkeep of slings utilized in load handling.

ASME, B30.9 (Slings)

Strict adherence to these standards guarantees both legal compliance and operational safety.

How Should Rigging Equipment Be Meticulously Inspected and Maintained for Peak Safety?

Regular inspections and proactive maintenance are key to identifying wear, corrosion, and mechanical damage before failures can occur. Essential practices include:

- Performing a thorough visual inspection for any cuts, abrasions, or discoloration on slings.

- Measuring wear against the manufacturer’s specified tolerances for slings.

- Maintaining meticulous inspection records, documenting dates, findings, and any corrective actions taken.

Consistent, diligent maintenance preserves equipment integrity and ensures operator readiness, preparing us for essential training requirements.

What Constitute Best Practices for Operator Training in Rigging Safety?

Comprehensive operator training integrates theoretical knowledge of load analysis with practical, hands-on experience to reinforce safe handling techniques. Training modules should encompass:

- Load capacity calculation to ensure precise and safe planning.

- Proper hitch selection for optimal load control in diverse configurations.

- Emergency procedure protocols to effectively mitigate risks during potential equipment failures.

Well-trained operators significantly reduce the likelihood of accidents and maximize equipment lifespan, paving the way for innovations that enhance lifting workflows.

How Can You Effectively Maintain and Extend the Lifespan of Your AmericanXpert Lifting Equipment?

Routine inspections and proactive maintenance are crucial for extending the service life of AmX slings while ensuring ongoing safety. Implementing structured maintenance protocols prevents failures and supports uninterrupted operations.

What Are the Essential Steps for Inspecting Slings?

Inspect slings by carefully checking for abrasion, cuts, core exposure, and discoloration before each use. Essential steps include:

- Conducting a thorough visual inspection for surface damage and any signs of loose stitching or broken wires (for Steel-tex).

- Measuring wear against the manufacturer’s specified limits for slings.

- Verifying tags to ensure correct identification and load rating information is present and legible.

Consistent, diligent inspections help detect issues early, leading to proper hardware maintenance procedures.

How Should Associated Rigging Hardware Be Properly Maintained?

Perform regular lubrication, load pin inspections, and corrosion checks on associated hardware like hoists, shackles, and chains to prevent mechanical failures. Key maintenance tasks include:

- Greasing bearings and gears within hoists to ensure smooth, efficient operation.

- Examining shackles for any pin deformation or thread wear.

- Checking for corrosion on all metal components.

Proper care of hardware components complements sling maintenance and informs timely replacement decisions.

When Is It Necessary to Replace Lifting and Rigging Equipment?

Equipment should be replaced when wear exceeds the manufacturer’s rated limits or when damage compromises its structural integrity. Key replacement criteria include:

- Cut depth exceeding 10% of the sling’s diameter or visible core strands (for synthetic slings).

- Broken wires or kinks in Steel-tex slings.

- Hook or shackle deformation exceeding 5% from their original dimensions.

Timely replacement preserves critical safety margins and prepares you for specific application requirements.

Round Sling Care Guide

Get the HOW TO posters to help your team stay safe and your gear stay strong. This quick-reference guides walk you through essential steps for maintaining round slings.

Regular inspection is key to preventing failure and protecting your crew. Download now!

Remember!

If you find any damage, remove the sling from service right away.

HOW TO CARE GUIDE FOR ROUND SLINGS?

Download this and other guides on our NEWS page

What Are the Most Prevalent Applications for AmericanXpert Lifting Equipment Across Various Industries?

AmX lifting equipment is frequently utilized in construction, manufacturing, marine, logistics, and heavy machinery handling sectors due to its inherent adaptability and proven reliability. Examining these applications highlights best practices for each sector before we conclude.

How Are AmX Slings Applied in Construction and Manufacturing?

IIn construction and manufacturing environments, AmX slings are instrumental in supporting steel beam placement, machinery installation, and the handling of pre-cast concrete. Typical uses include:

- Erecting steel frameworks using basket hitches on structural beams with polyester web slings.

- Installing heavy presses and molds that necessitate controlled load rotation with endless polyester round slings.

- Handling delicate concrete panels where surface protection is a critical concern, using polyester web slings.

- Lifting fabricated steel components with sharp edges using Steel-tex stage slings.

Applying slings effectively in these scenarios boosts site productivity and minimizes material damage.

What Lifting Solutions Are Ideal for Marine and Logistics Operations?

Marine environments often demand robust slings for efficient cargo handling on docks and vessels. Common applications include:

- Container loading and unloading utilizing sling-hoist assemblies.

- Handling mooring hardware with the use of appropriate slings.

- Pallet transfers within logistics yards employing automated sling pickers.

Selecting appropriate slings ensures dependable performance in various settings.

How Does Rigging Equipment Facilitate Heavy Machinery and Material Handling?

Rigging hardware, along with AmX slings, enables the precise positioning of heavy machinery components during assembly and maintenance. Key use cases include:

- Press alignment for industrial metalworking machinery using Steel-tex slings for their strength.

- Turbine installation within power generation facilities, often requiring high-capacity polyester round slings.

- Equipment relocation within manufacturing lines using mobile hoists and appropriate slings.

Integrating slings with specialized hardware streamlines complex lifts and maintains essential operational flow.

By mastering sling selection, adhering to compliance standards, and implementing maintenance best practices, you can significantly optimize safety and productivity across all your industrial operations. Regular inspections and timely equipment replacement are paramount for safeguarding operations and extending the lifespan of your lifting assets. Utilize this comprehensive guide as your roadmap for selecting, deploying, and maintaining best-in-class AmX lifting equipment for your most demanding material handling challenges.

Contact Us

At AmericanXpert, we value your inquiries and are committed to providing professional, customer-focused assistance. Please fill out the form below, and our friendly, knowledgeable team will respond promptly to address your needs. We look forward to helping you with any questions or concerns.